McLaren F1

The McLaren F1 is a sports car designed and manufactured by Gordon Murray and McLaren Automotive. On March 31, 1998, it set the record for the fastest production car in the world, 240mph (391km/h). As of April 2009, the F1 is surpassed by only three other production cars in sheer top speed, but is still the fastest naturally aspirated production car.

The car features numerous proprietary designs and technologies. It is lighter and has a more streamlined structure than even most of its modern rivals and competitors despite having one seat more than most similar sports cars, with the driver's seat located in the middle. It features a powerful engine and is somewhat track oriented, but not to the degree that it compromises everyday usability and comfort. It was conceived as an exercise in creating what its designers hoped would be considered the ultimate road car. Despite not having been designed as a track machine, a modified race car edition of the vehicle won several races, including the 24 Hours of Le Mans in 1995, where it faced purpose-built prototype race cars. Production began in 1992 and ended in 1998. In all, 106 cars were manufactured, with some variations in the design.

In 1994, AutoCar stated in a road test regarding the F1, "The McLaren F1 is the finest driving machine yet built for the public road." and that "The F1 will be remembered as one of the great events in the history of the car, and it may possibly be the fastest production road car the world will ever see."

Design and Implementation

Chief engineer Gordon Murray's design concept was a common one among designers of high-performance cars: low weight and high power. This was achieved through use of high-tech and expensive materials like carbon fibre, titanium, gold, magnesium and kevlar. The F1 was the first production car to use a carbon-fibre monocoque chassis.

The idea was first conceived when Murray was waiting for a flight home from the fateful Italian Grand Prix in 1988; Murray drew a sketch of a three seater sports car and proposed it to Ron Dennis, pitched as the idea of creating the ultimate road car, a concept that would be heavily influenced by the Formula One experience and technology of the company and thus reflect that skill and knowledge through the McLaren F1.

Quote from Gordon (translated from original Japanese article): "During this time, we were able to visit with Ayrton Senna (the late F1 Champion) and Honda's Tochigi Research Center. The visit related to the fact that at the time, McLaren's F1 Grand Prix cars were using Honda engines. Although it's true I had thought it would have been better to put a larger engine, the moment I drove the Honda NSX, all the benchmark cars—Ferrari, Porsche, Lamborghini—I had been using as references in the development of my car vanished from my mind. Of course the car we would create, the McLaren F1, needed to be faster than the NSX, but the NSX's ride quality and handling would become our new design target. Being a fan of Honda engines, I later went to Honda's Tochigi Research Center on two occasions and requested that they consider building for the McLaren F1 a 4.5 liter V10 or V12. I asked, I tried to persuade them, but in the end could not convince them to do it, and the McLaren F1 ended up equipped with a BMW engine."

Later, a pair of Ultima MK3 kit cars, chassis numbers 12 and 13, "Albert" and "Edward", the last two MK3s, were used as "mules" to test various components and concepts before the first cars were built. Number 12 was used to test the gearbox with a 7.4 litre Chevrolet V8 to mimic the torque of the BMW V12, plus various other components like the seats and the brakes. Number 13 was the test of the V12, plus exhaust and cooling system. When McLaren was done with the cars they destroyed both of them to keep away the specialist magazines and because they did not want the car to be associated with "kit cars".

The car was first unveiled at a launch show, 28 May 1991, at The Sporting Club in Monaco. The production version remained the same as the original prototype (XP1) except for the wing mirror which, on the XP1, was mounted at the top of the A-pillar. This car was deemed not road legal as it had no indicators at the front; McLaren was forced to make changes on the car as a result (some cars, including Ralph Lauren's, were sent back to McLaren and fitted with the prototype mirrors). The original wing mirrors also incorporated a pair of indicators which other car manufacturers would adopt several years later.

The car's safety levels were first proved when during a testing in Namibia in April 1993, a test driver wearing just shorts and t-shirt hit a rock and rolled the first prototype car several times. The driver managed to escape unscathed. Later in the year, the second prototype (XP2) was especially built for crashtesting and passed with the front wheel arch untouched.

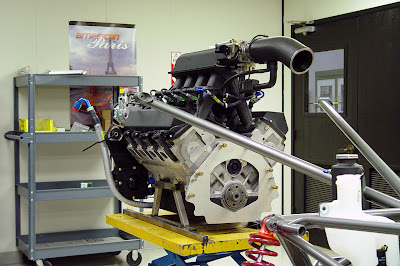

Engine

History

Gordon Murray insisted that the engine for this car be naturally aspirated to increase reliability and driver control. Turbochargers and superchargers increase power but they increase complexity and can decrease reliability as well as introducing an additional aspect of latency and loss of feedback, the ability of the driver to maintain maximum control of the engine is thus decreased. Murray initially approached Honda for a powerplant with 550 bhp (410kW; 560PS), 600mm (23.6 in) block length and a total weight of 250kg (551lb), it should be derived from the Formula One powerplant in the then-dominating McLaren/Honda cars.

When Honda refused, Isuzu, then planning an entry into Formula One, had a 3.5 V12 engine being tested in a Lotus chassis. The company was very interested in having the engine fitted into the F1. However, the designers wanted an engine with a proven design and a racing pedigree.

Specifications

In the end BMW took an interest, and the motorsport division BMW M headed by engine expert Paul Rosche[5] designed and built Murray a custom 6.1 L (6064 cc) 60-degree V12 engine called the BMW S70/2. At 627 hp (468 kW; 636 PS) and 266 kg (586 lb) the BMW engine ended up 14% more powerful and 16 kg (35 lb) heavier than Gordon Murray's original specifications, with the same block length. It has an aluminium alloy block and head, with 86 mm (3.4 in) x 87 mm (3.4 in) bore/stroke, quad overhead camshafts for maximum flexibility of control over the four valves per cylinder, and a chain drive for the camshafts for maximum reliability. The engine is dry sump.

The carbon fibre body panels and monocoque required significant heat insulation in the engine compartment, so Murray's solution was to line the engine bay with a highly efficient heat-reflector: gold foil. Approximately 25 g (0.8 ounce) of gold was used in each car.

The road version used a compression ratio of 11:1 to produce 627 hp (468 kW; 636 PS) at 7400 rpm and torque output of 480 ft·lb (651 N·m) at 5600 rpm. The engine has a redline rev limiter set at 7500 rpm.

In contrast to raw engine power, a car's power-to-weight ratio is a better method of quantifying acceleration performance than the peak output of the vehicle's powerplant. The standard F1 achieves 550 hp/ton (403 kW/tonne), or just 3.6 lb/hp. Compare with the Enzo Ferrari at 434 hp/ton (314 kW/tonne) (4.6 lb/hp), the Bugatti Veyron at 530.2 hp/ton (395 kW/tonne) (4.1 lb/hp), and the SSC Ultimate Aero TT with an alleged 1003 hp/ton (747.9 kW/tonne) (2 lb/hp).

The cam carriers, covers, oil sump, dry sump, and housings for the camshaft control are made of magnesium castings. The intake control features twelve individual butterfly valves and the exhaust system has four Inconel catalysts with individual Lambda-Sond controls. The camshafts are continuously variable for increased performance, using a system very closely based on BMW's VANOS variable timing system for the BMW M3; it is a hydraulically-actuated phasing mechanism which retards the inlet cam relative to the exhaust cam at low revs, which reduces the valve overlap and provides for increased idle stability and increased low-speed torque. At higher RPM the valve overlap is increased by computer control to 42 degrees (compare 25 degrees on the M3) for increased airflow into the cylinders and thus increased performance.

To allow the fuel to atomise fully the engine uses two Lucas injectors per cylinder, with the first injector located close to the inlet valve – operating at low engine RPM – while the second is located higher up the inlet tract – operating at higher RPM. The dynamic transition between the two devices is controlled by the engine computer.

Each cylinder has its own miniature ignition coil. The closed-loop fuel injection is sequential. The engine has no knock sensor as the predicted combustion conditions would not cause this to be a problem. The pistons are forged in aluminium.

Every cylinder bore has a nikasil coating giving it a high degree of wear resistance.

From 1998 to 2000, the Le Mans–winning BMW V12 LMR sports car used a similar S70/2 engine.

The engine was given a short development time, causing the BMW design team to use only trusted technology from prior design and implementation experience. The engine does not use titanium valves or connecting rods. Variable intake geometry was considered but rejected on grounds of unnecessary complication.

As for fuel consumption, the engine achieves on average 15.2 mpg, at worst 9.3 mpg and at best 23.4 mpg.

Chassis and Body

The McLaren F1 was the first production road car to use a complete carbon fibre reinforced plastic (CFRP) monocoque chassis structure. Aluminium and magnesium was used for attachment points for the suspension system, inserted directly into the CFRP.

The car features a central driving position – the driver's seat is located in the middle, ahead of the fuel tank and ahead of the engine, with a passenger seat slightly behind and on either side. The doors on the vehicle move up and out when opened, and are thus of the type butterfly doors.

The engine produces high temperatures under full application and thus cause a high temperature variation in the engine bay from no operation to normal and full operation. CFRP becomes mechanically stressed over time from high heat transfer effects and thus the engine bay was decided to not be constructed from CFRP.

Aerodynamics

The overall drag coefficient on the standard McLaren F1 is 0.32, compared with 0.36 for the faster Bugatti Veyron, and 0.357 for the current holder of the fastest car world record (as of 2008) – the SSC Ultimate Aero TT (in terms of top speed). The vehicle's frontal area is 1.79 square meters and the total Cx is 0.57. Due to the fact that the machine features active aerodynamics these are the figures presented in the most streamlined configuration.

The normal McLaren F1 features no wings to produce downforce (compare the LM and GTR editions), however the overall design of the underbody of the McLaren F1 in addition to a rear diffuser exploits ground effect to improve downforce which is increased through the use of two electric fans to further decrease the pressure under the car. A "high downforce mode" can be turned on and off by the driver. At the top of the vehicle there is an air intake to direct high pressure air to the engine with a low pressure exit point at the top of the very rear. Under each door is a small air intake to provide cooling for the oil tank and some of the electronics. The airflow created by the electric fans not only increase downforce, but the airflow that is created is further exploited through design, by being directed through the engine bay to provide additional cooling for the engine and the ECU. At the front, there are ducts assisted by an electric suction fan for cooling of the front brakes.

There is a small rear spoiler on the tail of the vehicle, which is dynamic, the device will adjust dynamically and automatically attempt to balance the center of gravity of the car under braking – which will be shifted forward when the brakes are applied. Upon activation of the spoiler a high pressure zone is obviously created in front of the flap, this high pressure zone is exploited—two air intakes are revealed upon application that will allow the high pressure airflow to enter ducts that route air to aid in cooling the rear brakes. The spoiler increases the overall drag coefficient from 0.32 to 0.39 and is activated at speeds equal to or above 40 mph (64 km/h) by brake line pressure.

Suspension

Steve Randle who was the car's dynamicist was appointed responsible for the design of the suspension system of the McLaren F1 machine. It was decided that the ride should be comfortable yet performance oriented, however not as stiff and low as that of a true track machine, as that would imply reduction in practical use and comfort as well as increasing noise and vibration, which would be a contradictory design choice in relation to the former set premise – the goal of creating the ultimate road car.

From scratch the design of the F1 vehicle had strong focus on centering the mass of the car as near the middle as possible by extensive manipulation of placement of i.a. the engine, fuel and driver, allowing for a low polar moment of inertia in yaw. The F1 has 42% of its weight at the front and 58% at the rear, this figure changes less than 1% with the fuel load.

The distance between the mass centroid of the car and the suspension roll centre were designed to be the same front and rear to avoid unwanted weight transfer effects. Computer controlled dynamic suspension were considered but not applied due to the inherent increase in weight, increased complexity and loss of predictability of the vehicle.

Damper and spring specifications: 90 mm (3.5 in) bump, 80 mm (3.1 in) rebound with bounce frequency at 1.43 Hz at front and 1.80 Hz at the rear, despite being sports oriented these figures imply the rather soft ride and will inherently decrease track performance, but again, the McLaren F1 is not in concept nor implementation a track machine. As can be seen from the McLaren F1 LM, McLaren F1 GTR et al., the track performance potential is much higher than that in the stock F1 due to fact that car should be comfortable and usable in everyday conditions.

The suspension is a double wishbone system with an interesting design, i.a. that longitudinal wheel compliance is included without loss of wheel control, which allows the wheel to travel backwards when it hits a bump – increasing the comfort of the ride.

Castor wind-off at the front during braking is handled by McLaren's proprietary Ground Plane Shear Centre – the wishbones on either side in the subframe are fixed in rigid plane bearings and connected to the body by four independent bushes which are 25 times more stiff radially than axially. This solution provides for a castor wind-off measured to 1.02 degrees per G of braking deceleration. Compare the Honda NSX at 2.91 degrees per G, the Porsche 928 S at 3.60 degrees per G and the Jaguar XJ6 at 4.30 degrees per G respectively. The difference in toe and camber values are also of very small under lateral force application. Inclined Shear Axis is used at the rear of the machine provides measurements of 0.04 degrees per G of change in toe-in under braking and 0.08 degrees per G of toe-out under traction.

When developing the suspension system the facility of electro-hydraulic kinematics and compliance at Anthony Best Dynamics was employed to measure the performance of the suspension on a Jaguar XL16, a Porsche 928S and a Honda NSX to use as references.

Steering knuckles and the top wishbone/bell crank are also specially manufactured in an aluminium alloy. The wishbones are machined from a solid aluminium alloy with CNC machines.

Tyres

The McLaren F1 uses 235/45ZR17 front tyres and 315/45ZR17 rear tyres. These are specially designed and developed solely for the McLaren F1 by Goodyear and Michelin. The tyres are mounted on 17x9 inches and 17x11.5 inches cast magnesium wheels, protected by a tough protective paint. The five-spoke wheels are secured with magnesium retention pins.

The turning circle from curb to curb is 13 m (42.7 ft), allowing the driver two turns from lock to lock.

Brakes

The F1 features unassisted, vented and crossdrilled brake discs made by Brembo. Front size is 332 mm (13.1 in) and at the rear 305 mm (12.0 in). The calipers are all four-pot, opposed piston types, and are made of aluminium. The rear brake calipers do not feature any handbrake functionality, however there is a mechanically actuated, fist-type caliper which is computer controlled and thus serves as a handbrake.

Servo assisted ABS brakes were ruled out as they would imply increased mass, complexity and reduced brake feel; however at the cost of increasing the required skill of the driver.

Gearbox and Miscellaneous

The standard McLaren F1 has a transverse 6-speed manual gearbox with an AP carbon triple-plate clutch contained in an aluminium housing. The second generation GTR edition has a magnesium housing. Both the standard edition and the 'McLaren F1 LM' have the following gear ratios: 3.23:1, 2.19:1, 1.71:1, 1.39:1, 1.16:1, 0.93:1, with a final drive of 2.37:1, the final gear is offset from the side of the clutch. The gearbox is proprietary and was developed by Weismann. The Torsen LSD (Limited Slip Differential) has a 40% lock.

The McLaren F1 has an aluminium flywheel that has only the dimensions and mass absolutely needed to allow the torque from the engine to be transmitted. This is done in order to decrease rotational inertia and increase responsiveness of the system, resulting in faster gear changes and better throttle feedback. This is possible due to the F1 engine lacking secondary vibrational couples and featuring a torsional vibration damper by BMW.

Interior and Equipment

Standard equipment on the stock McLaren F1 includes full cabin air conditioning, a rarity on most sports cars and a system design which Murray again credited to the Honda NSX, a car he had owned and driven himself for 7 years without, according to the official F1 website, ever needing to change the AC automatic setting. Further comfort features included SeKurit electric defrost/demist windscreen and side glass, electric window lifts, remote central locking, Kenwood 10-disc CD stereo system, cabin access release for opening panels, cabin storage department, four lamp high performance headlight system, rear fog and reversing lights, courtesy lights in all compartments, map reading lights and a gold-plated Facom titanium tool kit and first aid kit (both stored in the car). In addition tailored, proprietary luggage bags specially designed to fit the vehicle's carpeted storage compartments, including a tailored golf bag, were standard equipment. Airbags are not present in the car.

All features of the F1 were, according to Gordon Murray, obsessed over including the interior. The metal plates fitted to improve aesthetics of the cockpit are claimed to be 20/1000s of an inch thick to save weight. The driver's seat of the McLaren F1 is custom fitted to the specifications desired by the customer for optimal fit and comfort; the seats are hand made from CFRP and covered in light Connolly leather. By design the F1 steering column cannot be adjusted, however prior to production each customer specifies the exact preferred position of the steering wheel and thus the steering column is tailored by default to those owner settings; the same holds true for the pedals, which are not adjustable after the car has left the factory, but like the steering column the pedals are also tailored to each specific customer.

During its pre-production stage, McLaren commissioned Kenwood to create a lightweight car audio system for the car; Kenwood, between 1992 and 1998 used the F1 to promote its products in print advertisements, calendars and brochure covers. Each car audio system was especially designed to tailor to an individual's listening taste, however radio was omitted because Murray never listened to the radio.

Every standard F1 also has a modem which allows customer care to remotely fetch information from the ECU of the car in order to help aid in the event of a failure of the vehicle.

Purchase and Mintenance

Only 106 cars were manufactured, 64 of which were the standard street version (F1), 5 were LMs (tuned versions), 3 were longtail roadcars (GT), 5 prototypes (XP), 28 racecars (GTR), and 1 LM prototype (XP LM). Production began in 1992 and ended in 1998.[2] At the time of production one machine took around 3.5 months to make.

Up until 1998, when McLaren produced and sold the standard F1 models, they had a price tag of around 970 000 USD. Today the cars can sell for up to nearly twice that of the original price, due to the performance and exclusivity of the machine. They are expected to further increase in value over time.

Although production stopped in 1998, McLaren still maintains an extensive support and service network for the F1. There are eight authorized service centers throughout the world, and McLaren will on occasion fly a specialized technician to the owner of the car or the service center. All of the technicians have undergone dedicated training in service of the McLaren F1. In cases where major structural damage has occurred, the car can be returned to McLaren directly for repair.

On October 29 2008, an F1 road car (chassis number 065) was sold at an RM Automobiles of London auction for £2,530,000 (~US$4,100,000). This was the car from the McLaren showroom on Park Lane, London. With only 484 kilometers on its odometer, this pristine example set a world record for the highest price ever paid for an F1 road car.

Performance

In terms of sheer top speed, the F1 remains as of 2008 one of the fastest production cars ever made; as of July 2008 it is only succeeded by the Koenigsegg CCR, the Bugatti Veyron and the SSC Ultimate Aero TT. However, all of the superior top speed machines exploit forced induction to reach their respective top speeds – making the McLaren F1 the fastest naturally aspirated production car in the world.

Acceleration

0-30 mph (48 km/h): 1.8 s

0–60 mph (97 km/h): 3.2 s

0–100 mph (160 km/h): 6.3 s

0–124.28 mph (200.01 km/h): 9.4 s

0–150 mph (240 km/h): 12.8 s

0–200 mph (320 km/h): 28 s

30 mph (48 km/h)-50 mph (80 km/h): 1.8 s, using 3rd/4th gear

30 mph (48 km/h)-70 mph (110 km/h): 2.1 s, using 3rd/4th gear

40 mph (64 km/h)-60 mph (97 km/h): 2.3 s, using 4th/5th gear

50 mph (80 km/h)-70 mph (110 km/h): 2.8 s, using 5th gear

180 mph (290 km/h)-200 mph (320 km/h): 7.6 s, using 6th gear

0-400 m: 11.1 s at 138 mph (222 km/h)

0-1000 m: 19.6 s at 177 mph (285 km/h)

Top speed

With rev limiter on: 231 mph (372 km/h)

With rev limiter removed: 240 mph (390 km/h)

Track tests

Tsukuba Circuit, time trial: 1:04.62 on a hot lap.

Bedford Autodrome West Circuit, time trial: 1:21.20 on a hot lap, which is faster than the Ferrari Enzo at 1:21.30.

Millbrook Proving Ground in Bedfordshire, 2-mile (3.2 km) banked circuit, top speed test: An average speed of 195.3 mph (314.3 km/h), with a maximum speed of 200.8 mph (323.2 km/h) (driven by Tiff Needell using the XP5 prototype).

MIRA, 2.82-mile (4.54 km) banked circuit, top speed test: An average speed of 168 mph (270 km/h), with a maximum speed of 196.2 mph (315.8 km/h) (driven by Peter Taylor).

Record claims

The title of "world's fastest production road car" is constantly in contention, especially because the term "production car" is not well-defined.

The McLaren F1 has a top speed of 231 mph (372 km/h), restricted by the rev limiter at 7500 rpm. The true top speed of the McLaren F1 was reached in April 1998 by the five-year-old XP5 prototype. Andy Wallace (racer) piloted it down the 9 km straight at Volkswagen’s Ehra test track in Wolfsburg, Germany, setting a new world record of 240.1 mph (386.4 km/h) at 7800 rpm. As Mario Andretti noted in a comparison test, the F1 is fully capable of pulling a seventh gear, thus with a higher gear ratio or a seventh gear the McLaren F1 would probably be able to reach an even greater top speed—something which can also be observed by noticing that the top speed was reached at 7800 rpm while the peak power is reached at 7400 RPM.

.jpg)

.jpg)